Data courtesy2

Plastic 3D

printers

Produce high-quality prototypes and final polymer 3D parts with best-in-class isotropy, and gain optimized production and design freedom with uniquely predictable print times for any type of 3D part.

Transformative journeys in plastic 3D printing: Real stories of customer innovation and impact.

Data courtesy5

Metal 3D printer

Accelerate innovative designs and products, and efficiently produce high-quality 3D metal parts at scale.

Discover how companies have tapped into the power of HP Metal Jet technology to drive manufacturing innovation

Discover the HP advantage in Additive Manufacturing (AM) for high-end mass production environments

What are customers saying about HP Jet Fusion and Metal Jet 3D printers?

Discover real-life testimonials showing how various businesses are utilizing 3D printing to gain multiple advantages.

Partnership makes anything possible

Breakthrough digital technology alone isn’t enough. Today, you need a trusted partner who knows how to apply it effectively to help solve your specific supply-chain challenges.

Footnotes and disclaimers

- Images are courtesy of 3D Labs, Invent Medical, Skorpion Engineering, Avular, Sigma Ingegneria, Gimatic, Liq Eyewear, Schneider Electric.

- Image courtesy of Invent Medical.

- Image courtesy of BMW Group.

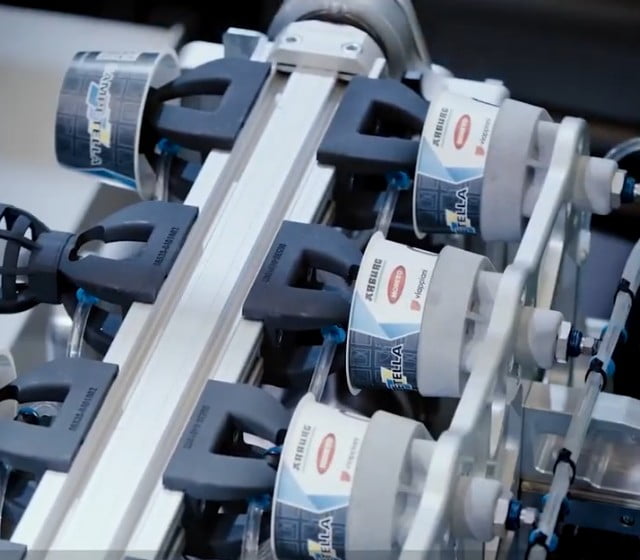

- Image courtesy of Campetella Robotic Center.

- Image courtesy of GKN Metallurgy.

- Image courtesy of John Deere.

- Image courtesy of Schneider Electric.

- Image courtesy of Volkswagen.

- Refers to enhanced production efficiency and job optimization with a consolidated dashboard that integrates data across industrial systems and continuous 3d printing with automated materials mixing, enclosed processing station, and natural cooling unit for HP Jet Fusion 3D printers.

- Portfolio of HP 3D printing plastic materials provide the following reusability ratios: HP 3D HR PA 12 S by Arkema up to 90%, PA 12 by Evonik up to 80%, PA 12 White up to 75%, PA 11 up to 70%, PA 12 GB up to 70%, PP up to 90%, TPUs up to 80% and TPA by Evonik up to 80%. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- Take back program for HP 3D HR PA 12 and PA 11 parts and powder. Arkema is specialized in regenerating high performance polymers, by collecting the materials to be recycled, analyzing them to guarantee the quality and then offering partially recycled grades with a more favorable LCA profile. Based on https://hpp.arkema.com/en/sustainability/virtucycle. Program available in Europe and US.

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2026 HP Development Company, L.P. The information contained herein is subject to change without notice.