Interested in HP molded fiber solutions?

Interested in HP molded fiber solutions?

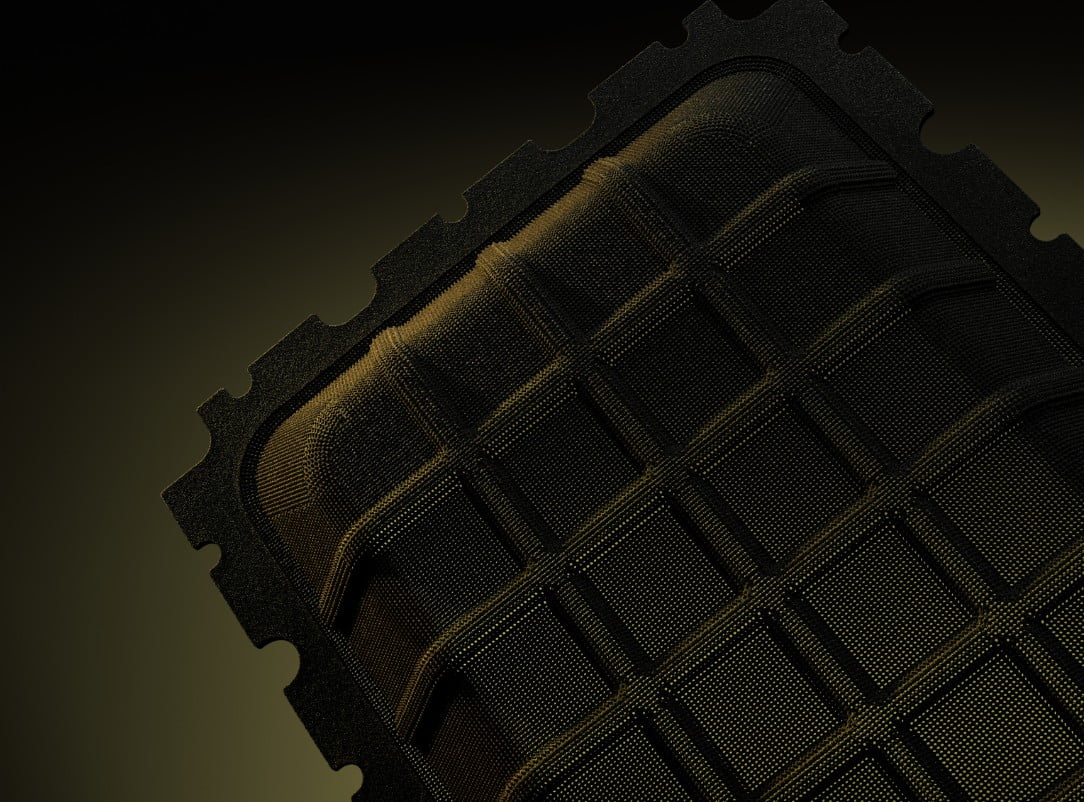

HP Molded Fiber Advanced Tooling Solution

Production-ready molded pulp tooling helps you offer new value to your customers.

Reimagine packaging

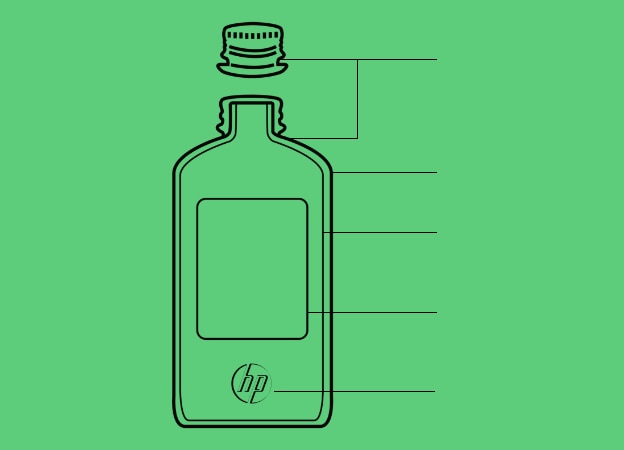

Dreaming of a brighter future, delivering an alternative to plastic bottles, designed to bring fiber-based products to market.

Production-ready molded pulp tooling helps you offer new value to your customers

Unlock greater production efficiencies and design opportunities.

Production-ready molded pulp tooling helps you offer new value to your customers

Unlock greater production efficiencies and design opportunities.

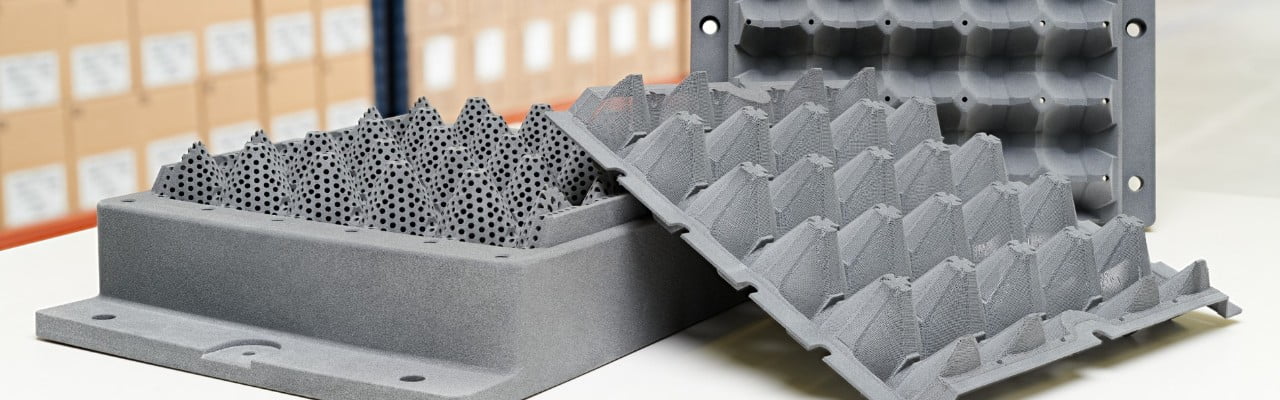

Transfer tool that reduces the need for drilling and is made of an engineering polyamide that is not subject to corrosion2 or calcification3 in water.

Packaging that can make a sustainable impact.

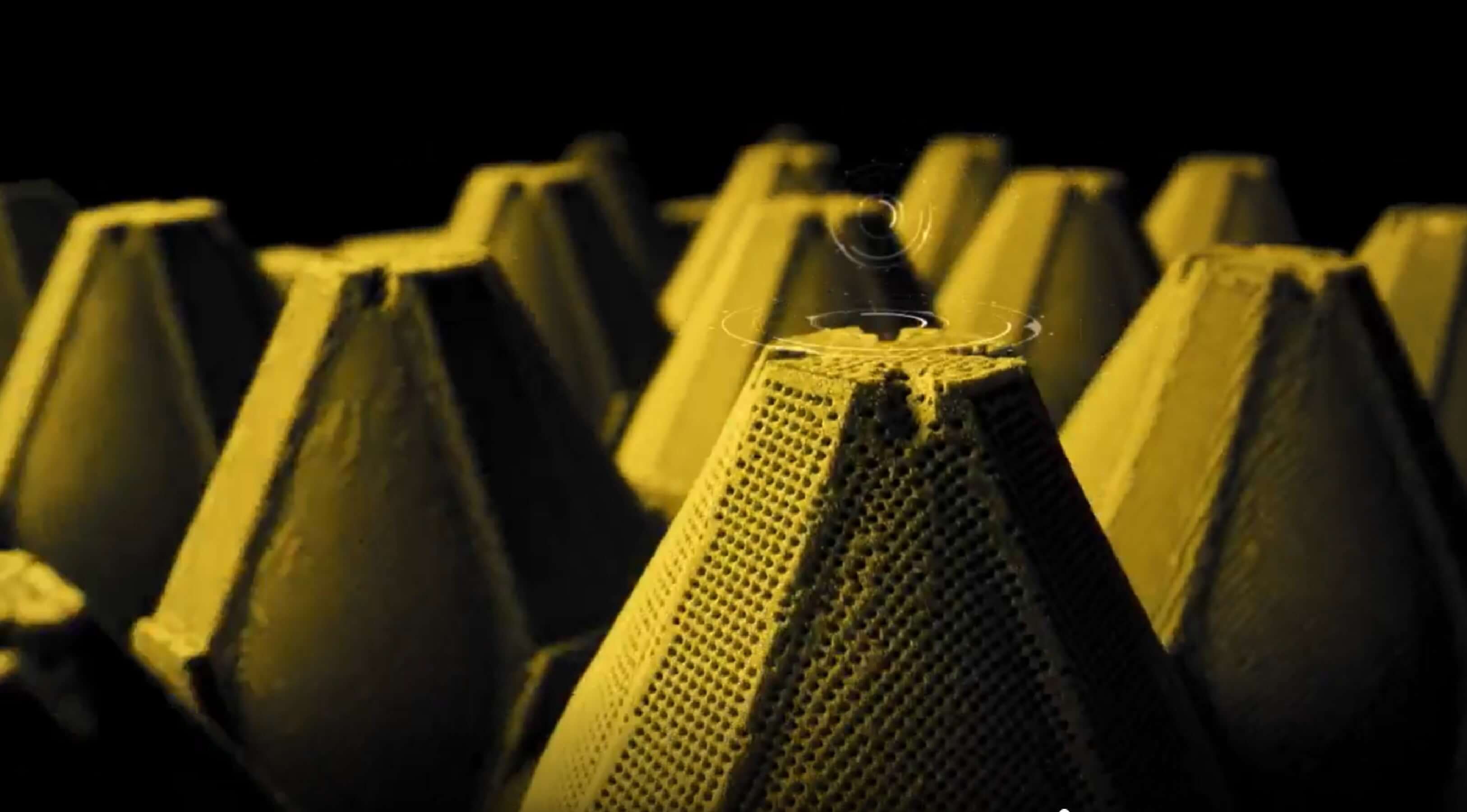

A digitally designed screen that can be cleaned, maintained, and replaced/changed in minutes. Requires less maintenance vs traditional processes as it is made from material that is not subject to corrosion2 or calcification3 in water.

Form tool that reduces the need for sectioning and drilling and is made of an engineering polyamide that is not subject to corrosion2 or calcification3 in water.

Rethinking every aspect of molded pulp production

See how these molded pulp manufacturers are doing it today.

Data courtesy4

Need greater production efficiencies?

PMP Inc. discovers new molded pulp production efficiencies, leveraging HP’s solution for lightweight production tooling and fast lead times.

Data courtesy5

Looking to open new revenue streams?

Western Pulp Products Company is discovering how easy it is to accommodate design iterations with HP technology that enables new levels of agility and versatility for tooling design and fabrication.

Data courtesy6

Looking to do cost-effective short runs?

Veritiv and Fiber Innovation are breaking barriers with HP’s solution, with molded pulp packaging that addresses their customer’s sustainability goals, and viable customized, short runs.

Data courtesy7

Want to lead industry transformation?

Pacific Pulp Molding Inc. shares how their customers can benefit from HP’s solution and why they believe it will set a new standard for tooling.

What are the molded fiber industry's experts saying?

Data courtesy8

Innofibre, Canadian global research center for cellulose products, partners with HP to validate new enhanced capabilities for HP´s Molded Fiber Advanced Tooling Solution.

Joe Grygny, leading industry expert for more than 25 years and consultant to HP, outlines how HP’s end-to-end service helps transform every aspect of molded fiber tooling production.

Data courtesy9

Industry-recognized tooler PMD has been in the molded fiber industry for over 40 years. Troy Mutton showcases the capabilities of the HP solution compared to traditional processes.

Get expanded tooling capabilities for greater production efficiencies and design opportunities

Rely on us to help you deliver quality molded fiber products, faster10

Increased OEE and reduced downtime11

.

Get expanded tooling capabilities for greater production efficiencies and design opportunities

.

How to order

You can rely on the HP Molded Fiber Advanced Tooling Solution to help you deliver quality molded fiber products, faster.10

How to order

You can rely on the HP Molded Fiber Advanced Tooling Solution to help you deliver quality molded fiber products, faster.10

1. Click on the Contact Us button and enter your data.

2. Securely12 send us your design file.13

3. HP experts review the design and send you a quotation based on the final design.14

4. You approve the final design and quotation.

5. Production starts15 using HP/s proprietary technology.

6. Your production-ready, quality tooling is ready to ship as quickly as 2 weeks;16, 17 Payment can now be completed.

Plastic waste is posing a threat to our planet and the future

353 million tonnes of global plastic waste in 2019, more than doubled since 2000

Only 9% of the plastics waste is recycled

40% of global plastic waste comes from packaging*

We need a better solution

*OECD Global Plastics Outlook Database: https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm

HP Fiber-based Packaging Solutions

What consumers are looking for in packaging

Fiber based • 100% Recyclable • Scalable • Reducing Plastic Usage

Our goal is to enable packaging solutions within a closed-loop recycling system – recyclable and reusable, again and again.

Reimagine your packaging with a fiber-based solution

A variety of materials are available.18

Different options for fiber are feasible.

We provide solutions that offer plastic reduction.

100% paper label.

Enhance the paper texture and imprint surface designs.

Bring your fiber-based products to market with us

Interested in learning more?

Fill out the form and one of our molded fiber tooling experts will get in touch with you.

Disclaimers

Note: all third parties referenced here have received parts produced through the HP Molded Fiber Advanced Tooling Solution.

1. This service is available in Canada, Eastern Europe, LatAM region, US, and Western Europe. Please contact us for more information on availability.

2. Polyamides in HP 3D High Reusability PA 11 material do not corrode with water (a common problem with metal tooling). Based on internal HP testing, August 2020. HP tools produced with HP 3D High Reusability PA 11 material were tested over 5 days at 50° C (122° F) using 4 different solvents (DI water - control, tap water, CaCO3 saturated, and 5 wt% aluminium potassium sulfate), and presented no visual signs of corrosion. For details, see: hp.com/go/MoldedFiberWhitepaper

3. Polyamides in HP 3D High Reusability PA 11 material do not present calcification signs with water (a common problem with aluminum tooling). Based on internal HP testing, November 2020. HP tools produced with HP 3D High Reusability PA 11 material were tested over 17 days at ambient temperature using 3 different solvents (DI water - control, tap water, CaCO3 super-saturated), and presented no visual signs of calcification or weight changes. For details, see: https://www.hp.com/go/MoldedFiberWhitepaper.

4. Data courtesy of Pulp Moulded Products Inc.

5. Data courtesy of Western Pulp Products Company

6. Data courtesy of Veritiv and Fiber Innovation

7. Data courtesy of Pacific Pulp Molding Inc.

8. Data courtesy of Innofibre.

9. Data courtesy of Pulp Moulding Dies Inc

10. Compared to traditional CNC and manual tooling processes as of June, 2020. Based on internal HP analysis and testing including expert interviews and a review of published market reports. 4-6 weeks average fabrication lead time when producing in CNC.

11. Compared to traditional CNC and manual tooling. Based on testing commissioned by HP and performed by Innofiber, February 2021.

12. Secure online platform offering password protected intellectual property and encrypted access control. For users only submitting design files, HP will be in contact for next steps.

13. Files supported: CAD file, Step (.stp), IGES (.igs). For additional documents, PDF and 2D drawing (.dwg) for critical dimension assessment.

14. If needed, HP will share recommended optimization changes to the design file. You may need to provide additional specifications in order to complete the ordering information.

15. Order status updates will be provided via email notifications.

16. Delivery as quickly as 2 weeks after HP receipt of design file, detailed specs, the tool design quotation approval, purchase order, and receipt of first payment. Shipping time not included.

17. Reduce inventory of safety stock replacement tooling with HP’s easily replaceable screens and on-demand ordering from our digital warehouse.

18. Aluminum on this specific representation.

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2026 HP Development Company, L.P. The information contained herein is subject to change without notice.