SAFELOG accelerates mobile robot deployment with HP SitePrint and Wuttke Ingenieure GmbH

“The print accuracy was up to 3 millimeters, exceeding our requirements and enabling optimal placement of the grid codes.” — Gérôme Stemmer, Director of Sales, SAFELOG

Project background

- Large intralogistics facility in Denmark

- Deploy thousands of fiducial QR markers to enable precise navigation of autonomous mobile robots in a 12,000 m² area

Highlights2

8x more productive

1 operator

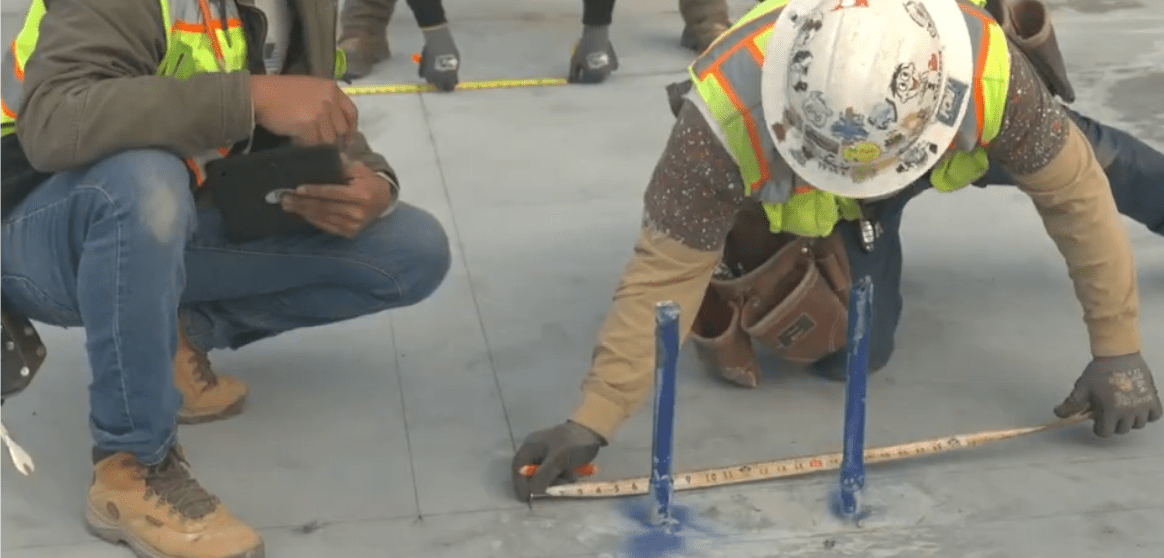

JN Bentley saves time and money using HP SitePrint for complex floor level process

"The robot makes it much faster and more accurate than an engineer manually doing it. For the job we did, an engineer would take about a week to achieve the same quality. HP SitePrint completed it in just a day and a half.” — Sean Clancy, Site Engineer

Project background

- Bromsgrove Sewage Treatment Works

- Conducting floor-level analysis before concrete panel installation to expand capacity and improve water treatment

- Project Size: 400 points and 100 concrete panels

Highlights2

7 times faster

1 operator

CSI Global accelerates Data Center deployment – from 30 to 300 points laid out per hour

“Laying out 5,000 points manually would have taken us forever. With HP SitePrint, we saved hundreds of hours.” — Mauro Arzuaga, Surveying Manager

Project background

- Construction of a large data center

- Scope of layout: Thousands of anchor plates for server racks (between 5,000–7,000 points)

- Critical requirement: Absolute precision, since racks and prefabricated components needed to fit exactly in place

Highlights2

10 times faster

1 operator

STL uses HP SitePrint to enable Geek+ AMR navigation

“For print we use a maximum of two days with HP SitePrint, and normally we would have used like two weeks for this. And we know we’re 100% reliable when we use it. There’s no human factors in it. We know when the printing is done, it’s accurate.” — Michael Petersen, STL

Project background

- Type of project: Installation of QR code navigation system for Geek+ AMR in warehouses

- Owner requirement: QR codes had to be positioned with ±2 mm accuracy to guarantee safe and reliable AMR operation

- Scope of layout: 1,500 QR code location printed across warehouses of 2,500m²

Highlights2

47% cost reduction

9x more productive

SCS delivers 14x faster layout in a medical facility warehouse with a high-density racking plan

The robotic layout compressed the schedule and reduced labor dramatically, making the team 14 times more productive than with manual methods and maintaining the 1/8-inch tolerance across the rack field.

Project background

- Description: Interior layout printing for the expansion of a medical manufacturing warehouse

- Main objective: Prepare a 110,000 sq. ft. facility for a high-density racking plan, including precise markings for racking, wire guidance, and life safety system coordination and tie-ins

Highlights2

50% cost reduction

2x more productive

FL Crane & Sons enjoy a 61% cost reduction in operational expenses with HP SitePrint

“HP SitePrint is faster than laying out with a robotic total station. It has supported us during many prefabricated, “just in time” delivered projects. On top, we only had to pay as we used the system instead of a lease where we were paying even if the system sat inactive.”— Jeremy Alvis, CM-BIM Division President

Project background

- Print interior layouts for walls in a hospital

- Project size; 84, 468 square feet of wall track

Highlights2

8 times faster

61% cost reduction

Valley Interior Systems goes from 30 to 300 linear feet of wall layout per hour with a single operator

"We were between 25 to 35 linear feet of wall layout per hour. With HP SitePrint we're doing 300 feet per hour, it's about 10x productivity increase." – Rick Hutchins, VP of Operations at Valley Interior Systems

Project background

- Print interior layouts for 18 different projects including commercial buildings, data centers and healthcare facilities

- Project size; Over 120,000 ft of wall track across 2 million sq ft

Highlights2

10 times faster

1 operator

ICI gets 8 times more productive in interior construction layout projects

“HP SitePrint saves us man hours on site doing the layout and allows us to spend more time doing QA/QC with a dedicated SitePrint operator also allowing the main superintendent/foreman to focus on his crews and looking forward into the project.” – Nick Hartline, ICC, LLC President

Project background

- Multiple projects, including hospitals, aerospace, technology projects, and schools

- Print interior layout for walls

- Project size; 60,000 square feet

Highlights2

4 times faster

8x more productive

Betonmast Buskerud-Vestfold achieves 8x more productivity at marking out

“We knew that digital surveying would improve quality, but now we also have data that confirms significant efficiency gains with 20%-30% faster progress for the carpenters. It creates room to push ahead in a very tight progress schedule.” – Christopher Carlsen, Betonmast’s Innovation Manager

Project background

- Horten Industrial Park (Vision Project), Goma School Project in Kristiansund

- Creating precise layouts for walls, partitions, sprinkler systems, and electrical elements

- Project size; 2 projects covering an area of 12,000 square meters

Highlights2

4 times faster

8x more productive

HP SitePrint helped Hoar Construction saving up to 18% of layout costs

“HP SitePrint has really sped up the operations of the physical layout on the ground." – Garrett Wheat, Project Manager

Project background

- Shannon Medical Center, Texas

- Multilevel parking garage

- MEP layout; 3,390 points (including text)

- Project Size: 16,485 ft² printed floor area

Highlights2

3 times faster

18% cost reduction

Brandt prints 1,136 points in a Data Center in just 5 hours, 5x faster than traditional processes

“Prior to investing in our HP SitePrint, some of our projects were presented with one of the HP competitors. With HP’s pay-per-use, we have been able to cut costs dramatically.” – Tanya Peddy, Virtual Field Technician Manager

Project background

- Temple data center

- Print the locations of bolt holes to place mechanical racks in a large data center

- Project size; 1,136 points over 50,000 ft²

Highlights2

5 times faster

6x more productive

Batson-Cook Construction gets a 34% cost reduction in self-perform layout

“By providing the VDC team with the layout information at the beginning of the project to correct clashes, the robot will save time in the back end, reducing man hours to rework incorrect layouts, and improving productivity up to 10 times.” – Clayton Guillory, Assistant VDC Manager, Batson-Cook Construction

Project background

- Biomedical Preparatory of the Health Science Center at a medical center

- Mark interior wall placement in a laboratory

- Self-perform layout activities, marking interior walls

- Project size; 70,000 sq ft of layout space

Highlights2

7 times faster

34% cost reduction

PCL Construction reduces layout cost by 86% at Vancouver Airport

“The Robot worked great. We had several radius steel stud/drywall ceiling bulkheads and curved tile floor borders that would have been very difficult to accurately layout any other way.” – Jason Palichuk – YVR Project Superintendent

Project background

- Vancouver Airport

- Decorative feature to be constructed in the ceiling at the airport

- Print layout for a decorative feature

- Project size; 3,280 ft (1000 m) of curved lines over a 6.458 ft² area (600 m²)

Highlights2

40 times faster

86% cost reduction

Winvic was able to complete the work 3 times faster with HP SitePrint

“With HP SitePrint we were able to complete the work 50-60% quicker than conventional methods – 6-7 days of setting out condensed into 2.5-3 days with SitePrint.” – Aman Mudan, Senior Engineer Winvic

Project background

- Lancaster Street, Birmingham, UK

- 33-storey residential building with living spaces, communal kitchens, study rooms, dining rooms, and lounge areas

- Full site set-out, including details for interior wall, electrical systems, ventilation systems, mechanical systems, and plumbing systems

- Project size; 3,000 square meters of coordinated floorplans

Highlights2

3 times faster

45% cost reduction

ArtLab Studios 10x more productive with HP SitePrint for tradeshow layout

“Trade Shows always have last-minute changes. HP SitePrint productivity allowed us to accommodate these changes without impacting the delivery of the layout.” – Eric Veenstra, Owner Artistic Director, ArtLab Studios

Project background

- Tradeshow layout at Messe Düsseldorf in Germany

- Mark stand locations and positions for lighting, electrical and sound systems

- Project size; 8,000 sq meter hall

Highlights2

2 times faster

10x more productive

ACCIONA executes a hospital marking drywall track 6 times faster compared to conventional layout processes

"Based on our experience, HP SitePrint has helped to improve our layout efficiency by around six times compared to a traditional manual method.” – José María Méndez Barragán, Hospital Technical Office Director

Project background

- Hospital Central do Alentejo in Évora, Portugal

- 10 floor building

- Drywall track marking layout scope; 1,951 meters

- Project size; 8,437m² printed floor area

Highlights2

6 times faster

12x more productive

Greenhatch Group completed a car manufacturing plant layout in a third of the expected time

“The accuracies that we’ve seen are incredible, and the speed of it as well. It’s probably 10 times faster, but also the amount of detail that you can put down is really key.” – Hayden Nash, Greenhatch Engineering Surveyor

Project background

- Car manufacturing, London

- Layout printing for assembly, picking, and packing equipment

- Designate positions for 1.751 pieces of equipment

- Project Size; 2.563 m2 of printed floor area

Highlights2

68% times reduction

49% cost reduction

Level 5 Drywall reduces layout time by eight days on a medical project with HP SitePrint

“We’re geared for projects costing less. Now, instead of taking three guys to do a layout, you’ve only got one and the other two are already laying track. You can move weeks ahead of schedule with HP SitePrint." –

G. Rivera, VP Operations

Project background

- 1900 North Loop Medical Center, California

- Medical research laboratory

- Drywall track marking layout scope: 2,315 ft

- Project size; 31,029 ft2 of floor space

Highlights2

9 times faster

36% cost reduction

Discover more about HP SitePrint with these customer testimonials

Contact us

Talk with an expert

Contact us to get pricing information and to take part in the HP SitePrint Early Access Program.

Stay informed

Sign up to stay informed on the evolution of HP SitePrint and an entire industry.

Footnotes and disclaimers

- Compared to Robotic Total Station assisted layout

- Compared to manual layout

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2026 HP Development Company, L.P. The information contained herein is subject to change without notice.